What Are the Types of Inventory and Do You Need Them All?

If you click to purchase a product or service based on our independent recommendations and impartial reviews, we may receive a commission. Learn more

Inventory management is a crucial part of the process when it comes to running an ecommerce business.

Correctly managing your ecommerce inventory can help to cut costs and streamline your fulfillment process.

There are various types of inventory that you need to get to grips with if you want your online store to run smoothly.

Here we explore the different types of inventory and whether or not you need them all.

What Is Inventory?

Inventory is everything that your online business uses to sell or produce your products, from the finished item to the raw materials that you use to make them.

Inventory therefore can literally be anything from sheets of silk to bananas – if you buy it or make it, it’s inventory for your business.

Brands will usually use an inventory management system to manage inventory levels, allowing you to monitor how much of each item you have and when it’s time to place another order.

Managing and optimizing your inventory levels is important as it helps to improve profits and productivity.

Types of Inventory

There are various types of inventory and understanding exactly what type of inventory your business uses will allow you to better manage and optimize your inventory levels.

Raw Materials

The inventory that you use to create your finished product is called raw materials. These are materials and items that you have purchased and have “in-stock” but that you haven’t yet used to create a finished product.

There are two types of raw materials:

- Direct materials that are used directly in the creation of your products.

- Indirect materials that are used as part of your overheads for the creation of your products.

For example, if you create leather bags, the leather you use to create your bags would be classed as a direct raw material. The lightbulbs or batteries you use inside your factory to make the bags would be classed as indirect raw materials.

Almost all businesses will use raw materials in some way.

Advice from the Experts

Top Tip! You don’t have to keep track of every tiny raw material you use. For example, screws or nails that are high-volume, low-cost can’t always be easily tracked and accounted for.

Work-in-Progress (WIP)

As the name suggests, Work-in-Progress (WIP) inventory is materials that are currently being worked on.

Put simply, whatever direct or indirect raw materials that your business is currently using to create a finished product are classed as WIP inventory.

There are various ways that WIP inventory can be used by businesses.

The most obvious is when materials are being used to create a currently unfinished product. For example, if you create curtains and take an inventory check when you’re halfway through the creation of a new set, the materials being used would be classed as WIP.

The materials being used to create the curtains are no longer raw materials as they’ve been “touched” but they’re not yet a finished product either.

It’s important to keep track of WIP inventory so that you can get an accurate picture of how much stock you have, allowing you to meet customer demand.

Finished Goods

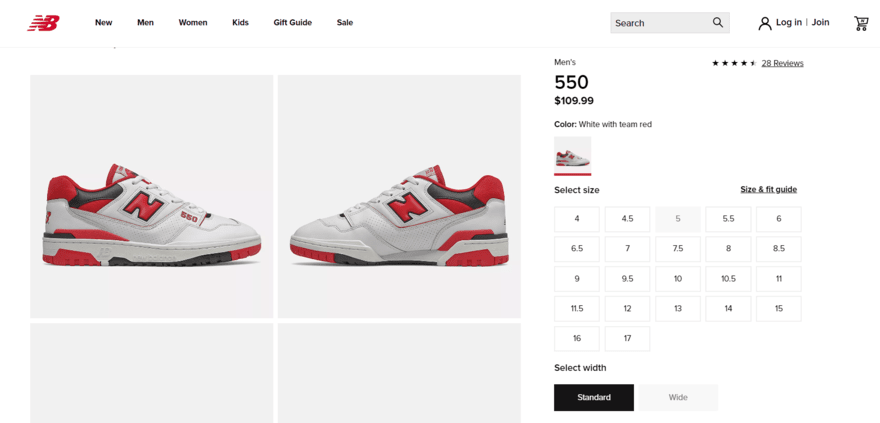

When we think of inventory, we likely naturally think of finished goods. These are the finished products that you have for sale on your website.

Any product that you are storing that is ready to be sold to a customer is classed as a finished good.

Finished goods can be anything from a pair of trainers to a coffee machine – if it’s ready to be sold, it’s a finished good. For non-ecommerce businesses, finished goods can refer to things such as a custom-built computer ready for an employee to use.

Keeping track of your finished goods inventory allows you to ensure your overall production is optimized to meet customer demand.

Advice from the Experts

Top tip! Remember, one brand’s finished goods may be another’s raw material. It all depends on where the item is heading next. If you’re ready to sell it to a customer, it’s finished goods.

Maintenance, Repair & Operations (MRO)

Maintenance, repair, and operations (MRO) inventory refers to the items that are required to create and assemble your products, but that aren’t included within the finished item.

MRO inventory can be anywhere, from inside your factory to in the back of the delivery van used to transport your products to customers.

For example, MRO inventory may be the gloves that workers need to wear in factories when handling your products or office supplies such as pens or paper.

No matter what your business is, the chances are you’ll use MRO inventory in some way.

Packing Material

The final type of inventory that you need to understand is packing materials.

Packing materials are anything that you use to, you guessed it, package up your products. This could be anything from envelopes and cardboard boxes to bubble wrap and tissue paper.

Packaging materials can often be forgotten about when it comes to managing inventory levels but it’s actually pretty important to keep a close eye on them. If you run out of packaging materials, you’ll have no way of shipping your products to your customers.

Similarly, if you have too many packaging materials, you’ll be forced to take up valuable storage space storing items that may never be used.

Other Types of Inventory

Alongside the five main types of inventory that we mentioned above, there are other different types of inventory that may also crop up as part of your online business.

Seasonal inventory – Seasonal inventory refers to items that sell at a higher rate at certain times of the year. It refers to the anticipation of higher demand such as during Black Friday sales.

In transit inventory – In transit inventory refers to stock that has been shipped and is already on its way to the customer.

Ready for sale inventory – Also known as available inventory, this is stock that is being stored and ready to go. If a sale is made, the item can be packaged up and shipped with no complications.

Allocated inventory – This is inventory that has been purchased by a customer and allocated a sales number, but has not yet been shipped. It’s inventory that cannot be sold to another customer as it has already been purchased.

Safety inventory – Safety inventory acts as a buffer to cover you if you face unprecedented circumstances or a problem with your supply.

Do I Need All Types of Inventory?

These different types of inventory are not mutually exclusive and you may find yourself dealing with all of them at any one time while you run your ecommerce business.

That doesn’t mean that you will definitely need all of the inventory options either. Every business is unique and so too are your inventory requirements.

For example, we would always recommend brands carry some levels of safety inventory in case something goes wrong but you may decide that you don’t need seasonal inventory based on your sales projections.

Of course, some online brands are able to deal with no inventory levels at all. If you decide to use a dropshipping business model or a third-party fulfillment company, your inventory storage and monitoring will be done for you.

Advice from the Experts

Top tip! Check out our expert guide to dropshipping versus ecommerce fulfillment to find out more about these options.

Managing Inventory

Managing inventory is important if you want every process within your online business to run smoothly. From the sourcing of materials and product creation to making sales, packaging, and shipping products, understanding your inventory levels is key.

There are various ways you can manage your inventory. You may opt for a spreadsheet where you manually update and track your stock or super small businesses that have tiny amounts of inventory might even use old-school pen and paper.

However, we would recommend investing in an inventory management system. The right inventory management software can help you to keep everything organized in one place, which is particularly useful if you have inventory stored across multiple locations.

Most systems will provide you with real-time updates on your inventory levels as well as alerts when something is running low. You’ll also be able to track which stage of the process each piece of inventory is currently in, helping to improve the productivity levels of your business too.

Types of Inventory: Summary

Inventory is a broad term and there are various different types of inventory that you may need to stock if you want to keep your online business running smoothly.

Understanding the different types of inventory and managing your own levels is important if you want to keep costs down and boost the productivity levels of your business.

To recap, the main types of inventory are:

- Raw Materials

- Work-in-Progress (WIP)

- Finished Goods

- Maintenance, Repair, and Operations (MRO)

- Packing Materials

Make sure to let us know in the comments which inventory levels you find most important for your online business!

Leave a comment